You need safe tools when you work where there are flammable gases or dust. An explosion proof floor scale lets you weigh things safely. It stops sparks or fires from happening. If you use the wrong devices, it can cause bad accidents. This puts everyone in danger. Safety and following rules keep you and your workplace safe. Today, safe weighing tools are very important for daily work.

Key Takeaways

Explosion-proof scales help keep people safe when weighing things in dangerous places with flammable gases or dust. They stop sparks and fires from happening, so workers stay safe.

When picking an explosion-proof scale, check for safety certifications like ATEX and IECEx. These certifications show that the scale meets safety rules.

It is important to know the difference between intrinsically safe and explosion-proof scales. Intrinsically safe scales use low energy so they do not make sparks. Explosion-proof scales keep any possible explosions inside a sealed box.

Choose a scale that fits your weighing needs and the place where you will use it. Think about how much weight it can hold, how accurate it is, and how strong it is. This helps the scale work well.

It is very important to take care of your scale and learn how to use it the right way. This stops accidents and keeps your equipment working safely.

Explosion Proof Floor Scale Features

What Makes a Scale Explosion Proof

It is important to know how an explosion proof floor scale is different from a regular industrial scale. The big difference is how the scale deals with dangerous situations. Some scales use intrinsic safety. This means the electronic parts use very little energy. They cannot make a spark hot enough to start a fire, even if something inside breaks. Other scales use explosion-proof enclosures. These enclosures are strong and sealed tight. If a spark makes a small explosion inside, the enclosure keeps it inside. It also cools any gases that come out so they do not start a fire outside.

Intrinsic safety (IS) is a way to prevent accidents. The electronic parts in the scale use so little energy that they cannot make a spark hot enough to start a fire. This is true even if a wire breaks or a part stops working.

Explosion-proof (or flameproof) enclosures keep explosions inside. The scale’s electronics can use normal energy levels, but they are inside a strong, sealed box. If a spark causes a small explosion inside, the box is strong enough to hold it. It also cools any gases that escape so they cannot start a fire outside.

The WEBOWT PHS Double-layer Analog Floor Scale is a good example of a strong explosion proof floor scale. Its double-layer design helps the scale handle heavy things and hard hits. This design keeps the weighing sensor in place, so you get correct numbers for a long time. The double-layer also gives extra safety from explosions, making your work safer.

Stainless steel is important for safety and strength. This material does not rust from chemicals or water. It keeps the scale strong and working well, even in hard places. The table below shows how stainless steel helps you:

Feature | Benefit |

Corrosion Resistance | Stops damage from chemicals, water, and other things, so the scale lasts longer and stays safe in dangerous places. |

Durability | All stainless steel parts make the scale work well for a long time. |

You also get a strong stainless steel frame and a smooth top plate. These parts make the explosion proof floor scale tough enough for dry chemical work and fertilizer plants. The IP6-rated load cell gives even more protection. It keeps the electronics safe from dust and water, so you can trust your scale in many dangerous places.

Key Safety Certifications

When you pick an explosion proof floor scale, you need to check for important safety certifications. These certifications show your scale is safe to use in dangerous places. Here are the most common certifications you should know:

ATEX Certification: Shows the scale is safe for places where explosions might happen.

IECEx Certification: Follows world rules for dangerous air.

FM Approval: Means the scale meets tough safety rules.

UL Certification: Shows the scale is safe for intrinsic safety in dangerous places.

These certifications help keep you safe and make sure you follow the rules. They also help you trust that your explosion proof floor scale will work well in dangerous places. The WEBOWT PHS Double-layer Analog Floor Scale meets these high standards, so you can use it in many jobs without worry.

How Explosion-Proof Scales Work in Dangerous Places

How They Stop Fires

Explosion-proof scales help keep people safe at work. They use special designs and technology to stop fires or explosions. There are two main types of these scales. One type is intrinsically safe. The other type is explosion-proof.

Intrinsically safe scales use a way to stop fires before they start. They keep the energy inside the scale very low. This means the scale cannot make a spark or get too hot. Even if something breaks, it will not start a fire. Explosion-proof scales use a strong box to keep you safe. All the electric parts are inside this sealed box. If a spark makes a small explosion, the box keeps it inside.

Here is a table that shows how the two types are different:

Feature | Intrinsically Safe (IS) | Explosion-Proof (XP) |

Safety Concept | Stops fires by using less energy. | Uses a strong box to hold explosions. |

Design | Uses small, light parts. | Uses heavy, sealed boxes. |

Maintenance | You can fix it while it is on. | You must turn it off to open it. |

Environment | Good for the most dangerous places. | Used in less risky places. |

Weight & Cost | Lighter and costs less. | Heavier and costs more. |

Explosion-proof scales have many ways to stop fires:

They use low-power parts to keep things safe.

Safety barriers stop energy from moving to unsafe places.

Some use fiberoptic cables and batteries to stop sparks.

You can adjust the scale without going into dangerous areas.

Built-in checks help you find problems from a safe spot.

Temperature sensors watch for heat changes. These sensors help stop the scale from getting too hot. They keep the scale safe and help stop accidents.

All these things work together to keep you and your workplace safe.

Where You Find These Scales

Explosion-proof scales are used in many dangerous places. These places have gases, dust, or fibers that can catch fire. The table below shows the main types:

Class | Description |

Class 1 | Places with flammable gases or vapors. |

Class 2 | Places with dust that can burn. |

Class 3 | Places with fibers that can catch fire. |

You might see these places in oil refineries, chemical plants, grain silos, or textile factories. Each place has its own dangers. Explosion-proof scales help you work safely in all these places. You can trust them to give you the right weight and keep you safe.

Applications of Explosion Proof Scales

Image Source: unsplash

Explosion proof floor scales keep workers safe in many jobs. You can use them where fire or explosions might happen. The WEBOWT PHS Double-layer Analog Floor Scale works well for many tasks. It is strong and has safety features. This makes it a good choice for different industries.

Oil and Gas Industry

Oil and gas work can be dangerous. There are flammable gases and vapors. Regular scales can cause problems because:

Sparks from electric parts can start fires.

Too much heat can make dust catch fire.

Broken wires can make sparks.

Explosion proof scales help you follow safety rules. They protect your team and equipment. You lower the chance of accidents and keep everyone safe.

Chemical and Pharmaceutical Plants

You need safe and exact weighing in these plants. Explosion proof scales stop sparks and heat. This helps prevent fires. These scales also help you follow strict safety rules. Here is how they help:

Feature | Description |

Intrinsically Safe Design | Stops sparks or heat in dangerous areas. |

Compliance | Meets standards like ATEX and IECEx for safe use in explosive environments. |

Accurate Measurements | Gives you precise weights for safety and quality. |

You can trust the WEBOWT PHS scale for weighing materials safely.

Food Processing and Agriculture

Food and farm work often has dust and gases. These can catch fire easily. Explosion proof scales help you stay safe. Here are some problems you might face:

Challenge | Explanation |

Risk of ignition from equipment | Sparks can cause explosions in dusty areas. |

Compliance with safety regulations | You must follow strict rules to prevent accidents. |

Equipment failure | Broken equipment can ignite combustible materials. |

Presence of combustible dust and gases | You need careful scale selection and maintenance. |

The WEBOWT PHS scale is made of stainless steel. Its sealed design is great for these places.

Mining Operations

Mining sites have explosive materials and coal dust. Explosion proof scales help you weigh these things safely. You keep your work running well and follow safety rules. You can:

Explosion proof scales like the WEBOWT PHS model give you safety and reliability in mining.

Intrinsically Safe Scales and Compliance

Intrinsically Safe Scales Overview

You need intrinsically safe scales for risky places. These scales use very little energy. They do not make sparks or get hot. You can use them in many dangerous areas. These areas have flammable gases, dust, or fibers.

Here is a table that shows where you might use intrinsically safe scales:

Class/Division | Description |

CLASS I | Flammable Gases or Vapors |

CLASS II | Combustible Dusts |

CLASS III | Ignitable Fibers or Flyings |

DIVISION 1 | Hazard exists under normal conditions. |

DIVISION 2 | Hazardous material is handled, processed or stored. Hazard is not normally present, but may be released due to accident or equipment malfunction. |

You can trust these scales to keep you safe. They help you follow safety rules. They protect you and your team.

Meeting Industry Standards

You must use scales that meet strict rules. These rules make sure your equipment is safe. Many groups set these rules. The table below shows some important standards:

UL Standard | Description | Harmonized With |

UL 913 | Requirements for IS equipment used in Class I, II, III Divisions | No |

UL 60079-11 | Aligns with IEC 60079-11 for IS equipment in Zones | IECEx, ATEX |

UL 121201 | Applies to associated apparatus used outside the hazardous area | IEC 60079-25 |

You need to know which rules apply in your country. In North America, you need UL certification for these scales. In Europe, you need ATEX certification. Each region has its own tests and rules. You must follow these to keep your workplace safe and legal.

ATEX certification is very important in Europe. It has strict rules for equipment in explosive places. UL certification is used in North America. It checks electrical and safety parts. If you work in more than one country, you must understand these rules. This helps you pick the right scales for your job.

Choosing the Right Explosion Proof Scale

Selection Factors

When you pick an explosion proof scale, think about your job and where you will use it. Here are the most important things to remember:

Weighing Requirements: Decide what you need to weigh and how often you will do it. Check if the scale can hold enough weight and is accurate for your work.

Environmental Factors: Look at the temperature, humidity, and dust in your area. Some places have chemicals or water that can hurt your equipment.

Accuracy and Calibration: Make sure your scale is accurate for your industry. Easy calibration helps you keep your results right.

Construction and Durability: Choose a scale made from strong materials. Stainless steel is good for tough jobs.

Safety Features: Look for overload protection and safety certifications. These features help stop accidents.

Connectivity and Data Management: Some jobs need scales that connect to computers or other devices.

Maintenance and Support: Good support and easy setup and care save you time and money.

Cost-Effectiveness: Think about how much the scale will help you over time, not just the price.

The WEBOWT PHS Double-layer Analog Floor Scale is a good example. You can pick the platform size and how much it can hold, from 300 kg to 3000 kg. Its stainless steel body and IP6 load cell make it strong for many types of explosion proof scales and places. The intrinsically safe design helps you work safely in risky areas.

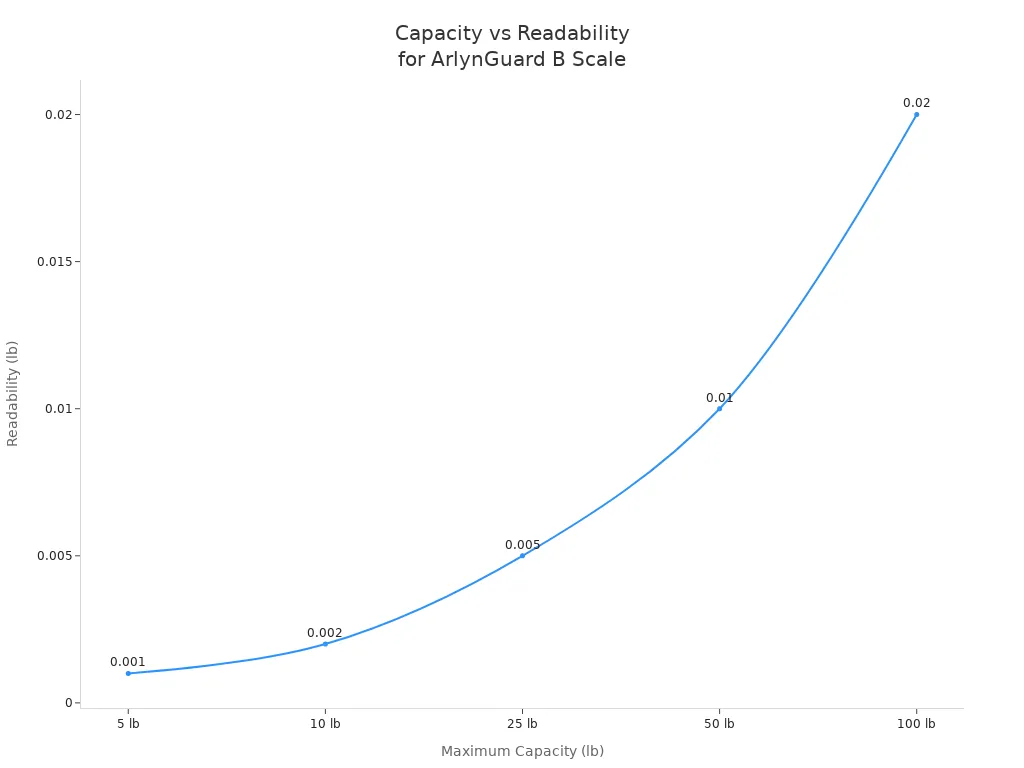

Scale Type | Maximum Capacity | Readability |

ArlynGuard B Scale | 5 pounds | .001 pounds |

| 10 pounds | .002 pounds |

| 25 pounds | .005 pounds |

| 50 pounds | .01 pounds |

| 100 pounds | .02 pounds |

Cylinder Scales | 60 - 400 pounds | .02 - .1 pounds |

Platform Scales | 500 - 1,000 pounds | .1 - .2 pounds |

Common Mistakes to Avoid

You can make mistakes when picking a scale for dangerous places. Here are some common mistakes:

Not thinking about how much weight you need or how accurate the scale is.

Picking a scale without the right certifications for your area.

Forgetting about how to set up and take care of the scale.

Choosing a scale that cannot handle your work area.

Not checking if the scale works with your data systems.

If you avoid these mistakes, you will find a scale that keeps you safe and helps your work go well.

Explosion proof and intrinsically safe scales keep you safe at work. They help protect your team from danger. You also follow important safety rules when you pick the right scale. Here are some steps to remember:

Look for things that could be dangerous in your workplace.

Choose equipment that follows safety rules.

Teach your team how to use the scales and check them often.

The WEBOWT PHS Double-layer Analog Floor Scale is strong and safe. It is easy to use and gives correct results. Pick smart tools to make your work safer and better.

FAQ

What are explosion-proof scales and why do you need them?

Explosion-proof scales help you weigh things safely. You use them in places with dangerous gases or dust. These scales stop sparks or heat from causing explosions. They help keep your team and equipment safe.

How do explosion-proof enclosures work in hazardous locations?

Explosion-proof enclosures cover the scale’s electronics. If something explodes inside, the enclosure holds it in. This stops fire or gas from spreading. The design helps keep you safe at work.

Where do you use explosion-proof scales most often?

You see explosion-proof scales in oil refineries and chemical plants. These places have flammable gases or dust. Explosion-proof scales help prevent explosions and keep everyone safe.

What makes explosion-proof scales different from regular scales?

Explosion-proof scales have special parts and strong enclosures. These features stop sparks and heat from causing explosions. You can trust them in dangerous places where regular scales might not work.

How do you maintain explosion-proof scales in hazardous locations?

You clean explosion-proof scales often and look for damage. You follow safety rules for dangerous places. If you find a problem, you fix it quickly. This keeps the scales working well and helps prevent explosions.