In the complex landscape of industrial operations, where precision meets potential hazards, safety stands as the unshakable foundation upon which all productivity and progress rely. Among the many tools designed to uphold this safety, explosion proof scale indicators emerge as unsung heroes, playing a critical role in environments where even the smallest spark could ignite disaster. These specialized devices are not mere add-ons to weighing systems but essential components that bridge the gap between accurate measurement and hazard prevention, ensuring that industrial processes involving flammable gases, vapors, dust, or liquids can proceed without compromising the well-being of workers or the integrity of facilities.

To understand the significance of explosion proof scale indicators, one must first grasp the unique challenges of explosive atmospheres. In industries such as petrochemical processing, oil refineries, chemical storage, pharmaceutical manufacturing, and mining, the air can be saturated with substances that, when combined with an ignition source, pose catastrophic risks. Traditional electronic devices, including standard scale indicators, generate heat or electrical sparks during operation—byproducts that are harmless in ordinary settings but deadly in these high-risk zones. Explosion proof scale indicators are engineered to eliminate this threat, serving as the "brain" of the weighing system while containing any internal ignition sources, thus preventing them from interacting with the surrounding hazardous environment.

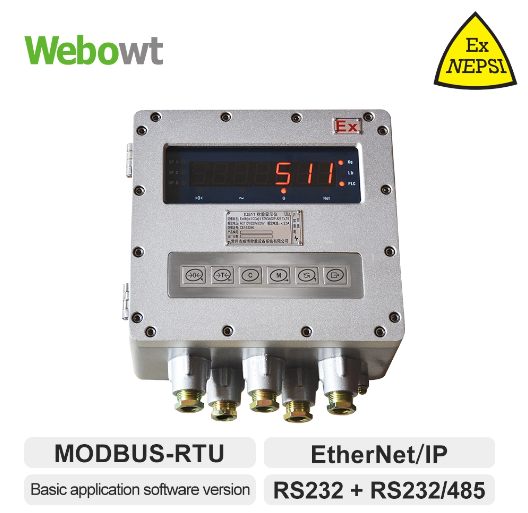

At their core, explosion proof scale indicators function by processing and displaying weight data from connected load cells, much like standard indicators. However, their design incorporates a suite of protective measures that set them apart. The housing, often made from robust materials such as cast aluminum or stainless steel, is constructed to withstand internal explosions. This means that if a spark were to occur within the device—due to electrical arcing or component failure—the enclosure would contain the blast, preventing flames or pressure from escaping and igniting the external atmosphere. Additionally, these indicators are sealed to prevent the ingress of flammable substances, ensuring that no hazardous gases or dust can penetrate the casing and come into contact with internal electrical components.

Beyond their protective housing, explosion proof scale indicators are equipped with specialized electrical components that minimize ignition risks. They use low-voltage circuits and are designed to limit the release of energy, reducing the chance of sparking. Many models also feature intrinsic safety, a design principle where the electrical energy within the device is kept below the threshold required to ignite a flammable mixture. This dual approach—combining physical containment with energy limitation—makes explosion proof scale indicators uniquely qualified to operate in zones classified as hazardous by international standards, such as ATEX in Europe or NEC in the United States.

The importance of these indicators extends beyond hazard prevention; they also ensure the accuracy and reliability of weight measurements, which are critical for maintaining product quality, regulatory compliance, and operational efficiency. In industries where precise dosing of chemicals, blending of materials, or filling of containers is required, even minor measurement errors can lead to costly waste, product defects, or non-compliance with safety regulations. Explosion proof scale indicators are calibrated to deliver the same level of precision as their non-explosion-proof counterparts, often with advanced features such as digital filtering to reduce the impact of vibrations in industrial settings, tare functions for net weight calculations, and data logging capabilities for process traceability.

Another key aspect of explosion proof scale indicators is their role in regulatory compliance. Governments and industry bodies worldwide have strict standards governing equipment used in hazardous areas, aiming to prevent accidents and protect workers. Explosion proof scale indicators must undergo rigorous testing and certification to meet these standards, ensuring that they can operate safely under the specific conditions of their intended use. For example, they may be certified for use in zones where flammable gases are continuously present (Zone 0) or where they may occasionally occur (Zone 1), with corresponding design adaptations to handle these scenarios. By using certified explosion proof scale indicators, businesses not only avoid legal penalties but also demonstrate a commitment to safety that enhances their reputation among clients, employees, and regulatory authorities.

The practical applications of explosion proof scale indicators are diverse and far-reaching. In petrochemical plants, they are used to weigh raw materials and finished products, such as gasoline or diesel, where the presence of volatile hydrocarbons creates a constant explosion risk. In pharmaceutical manufacturing, they ensure precise measurements of flammable solvents used in drug production, maintaining both safety and product consistency. In mining operations, they weigh explosive materials or coal dust-laden materials, where even a small spark could trigger a devastating blast. In each of these scenarios, the explosion proof scale indicator acts as a critical link, allowing essential weighing operations to proceed without putting lives or facilities at risk.

Durability is another hallmark of explosion proof scale indicators, as they are designed to thrive in harsh industrial environments. These settings often involve extreme temperatures, humidity, vibration, and exposure to corrosive substances—conditions that would quickly degrade standard electronic equipment. Explosion proof indicators are built with rugged components and protective coatings that resist corrosion, while their enclosures are sealed to prevent damage from moisture or dust. This durability ensures that they can provide reliable performance over extended periods, reducing downtime and maintenance costs, and further contributing to overall operational efficiency.

Moreover, modern explosion proof scale indicators often integrate with other industrial systems, enhancing their utility. They may feature communication ports such as RS-485 or Ethernet, allowing them to transmit weight data to centralized control systems, inventory management software, or cloud-based platforms. This connectivity enables real-time monitoring of weighing processes, facilitating data-driven decision-making and improving process visibility. For example, in a chemical plant, weight data from explosion proof indicators can be integrated with process control systems to automatically adjust material dosages, ensuring consistency while minimizing human intervention in hazardous areas.

In summary, explosion proof scale indicators are indispensable tools in industrial safety, combining precision measurement with robust hazard prevention to enable safe operations in explosive atmospheres. Their specialized design, regulatory compliance, durability, and integration capabilities make them essential for industries where safety and accuracy are equally critical. By investing in high-quality explosion proof scale indicators, businesses can protect their workforce, comply with regulations, maintain product quality, and ensure the continuity of their operations. For those seeking a reliable partner in this critical area, choosing a reputable manufacturer is key—and Webowt stands out as a trusted provider, offering top-tier explosion proof scale indicators that meet the highest standards of safety, precision, and durability, ensuring that your industrial processes remain both efficient and secure.